The European Green Deal emphasizes the importance of clean energy technologies, and lithium-ion batteries (LIB) are central to achieving the EU’s climate neutrality target by 2050. Nonetheless, LIBs are considered dangerous goods due to the hazardous materials in their composition that put at risk people, goods, facilities, and environment. Past accidents and live demonstrations where BATRAW has participated have highlighted the need for safety protocols when handling, transporting, and storing these devices. These requirements were reflected in Regulation (EU) 2023/1542 concerning batteries and waste batteries, as well as the different international agreements on transportation of dangerous goods (Figure 1).

In the BATRAW project the shipment of sample batteries is frequent, making it essential to establish clear guidelines on battery pack handling and transportation. RECYCLIA, in collaboration with other partners, has finalized a report outlining fundamental safety aspects that need to be known by all actors handling LIBs. The Guidelines on battery pack handling and transportation were submitted in October and are awaiting the Commission’s review. Its recent submission does not imply that safety measures were previously neglected though; rather, it provided an opportunity to compile and summarize knowledge acquired over the project’s first two years, combined with the authors’ prior experience.

Starting with the basics, the main concerns with these devices are the sudden onset of thermal runaway or short-circuiting, which can quickly escalate into a violent, self-sustaining fire. These events can be triggered by exposure to extreme temperatures, mechanical stress caused by impacts, or a simply defective or loose component.

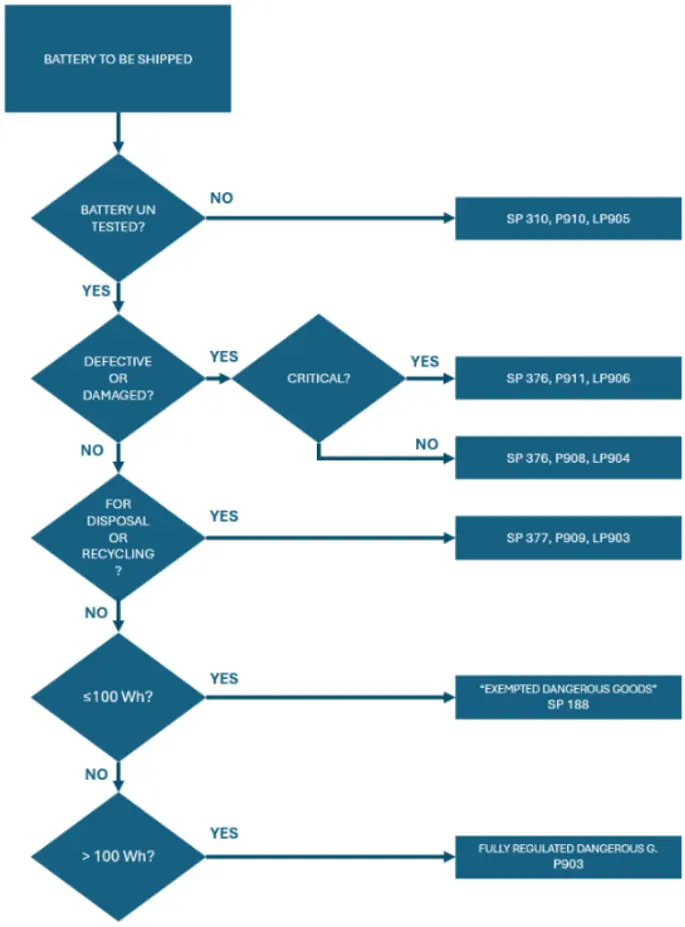

Furthermore, not all batteries respond the same way to external factors and so they do not present the same type of level of risk. Different classifications divide batteries according to application, weight and capacity, technology/chemistry, or physical condition. For the purpose of shipping, it is especially critical to assess the integrity of the battery, as stated in the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

If the battery shows no signs of damage and meets the test requirements outlined in the Manual of Tests and Criteria, Part III, subsection 38.3, it is considered undamaged. In this case, the packaging requirements are less strict than those for batteries classified as damaged or critically damaged. Based on these conditions, the ADR specifies distinct packaging instructions, as illustrated in Figure 2.

Regardless of the result of the assessment, a mandatory step when preparing battery cells, modules or packs for shipping is electrically insulating the terminals by means of, e.g., mineral-based calcium grease spray, plugs firmly attached to the poles, or insulating tape. In addition, they must be properly protected from impacts to prevent mechanical stress.

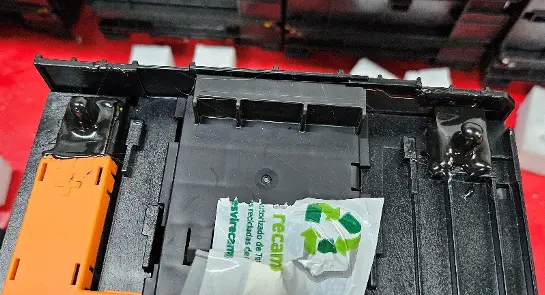

Diving deeper into the packaging, a popular solution is a sealable pallet box used in combination with bags filled with non-combustible material whose components bind toxic and flammable gases while cooling down fire. Additionally, bags are distributed between the modules to prevent impacts and minimize movement (Figure 4). The pictures below show the boxes purchased and used for shipments between BATRAW partners. At the moment, they are being used by CESVIMAP, who will soon deliver battery modules from Ávila (Spain) to ORANO’s facilities in Bessines sur Gartempe (France) for characterization, testing and later on, conducting the second pilot test of the project. It is important to mention that traceability is key during these operations, reason why the Digital Battery Passport will soon be mandatory, providing a common platform for data sharing.

All things considered; risks do not end at the warehouse. While transport could be perceived as more critical due to handling operations and exposure to varying environmental conditions, storage entails its own risks due to less frequent supervision combined with a greater volume of materials that can amplify hazards. For this reason, the report would not be complete without basic notions in this regard, including emergency protocols.

This brief article only manages to offer a glimpse into a few of the aspects to consider during LIB transportation. For the benefit of all stakeholders in the sector, we aim to publish the full report on our website as soon as it receives approval from the Commission.