BeePlanet

Our partner from Navarre (Spain) has been investigating the steps to be taken prior to the disassembly of batteries. Its findings, reflected in two already submitted reports:

- D3.4 Report on identification, characterization, and deactivation of battery packs.

- D3.9 Report on working station for identification and deactivation of battery packs.

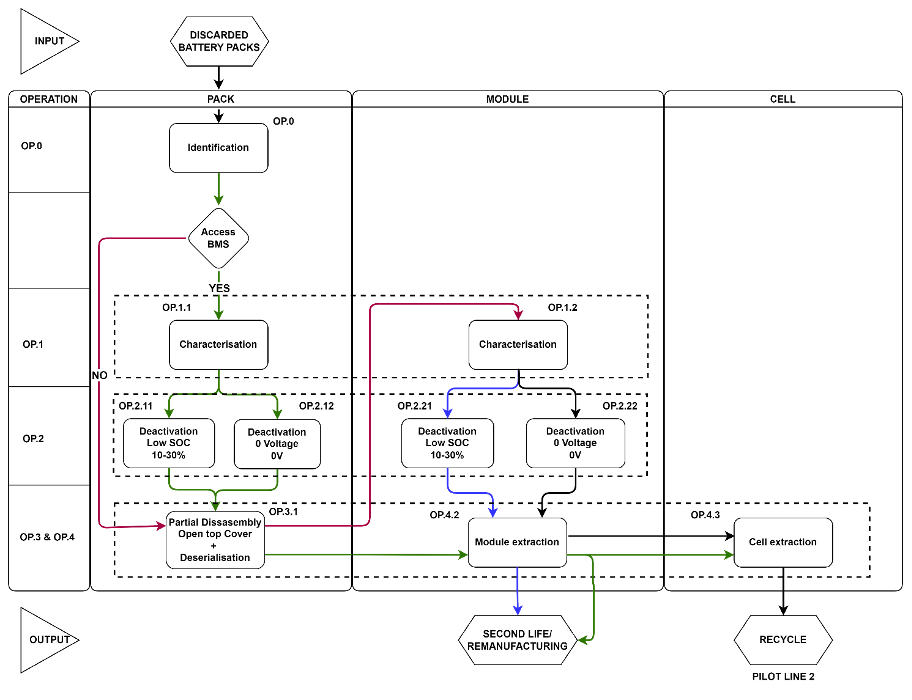

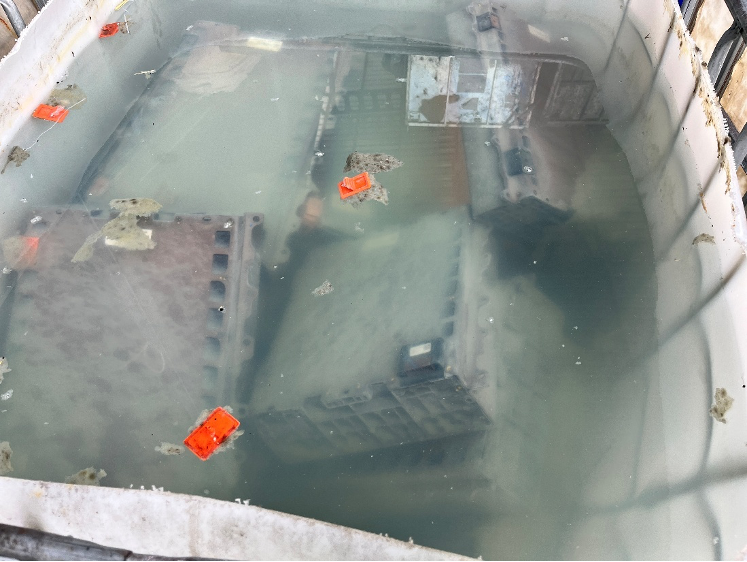

First, the methodology for the operations before the Electric Vehicle (EV) battery pack dismantling was presented (figure 1). The report also included the complexities of identifying different types of EV battery packs while assessing their performance and state of health. Furthermore, essential deactivation protocols for safe handling and disposal during recycling were also covered.

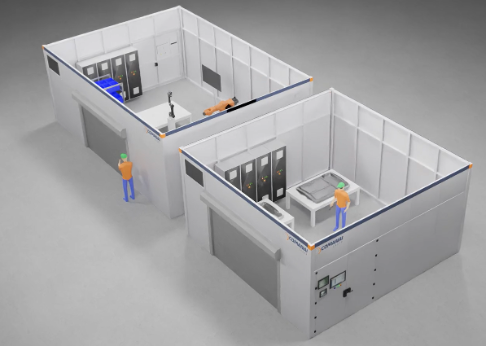

Regarding the new working stations, BeePlanet is overseeing and guiding the progress made by the other task partners. The goal is to gather all the necessary information and finalize the details needed for the first draft, culminating in the design freeze of the workstations to start the construction of them in the coming months.

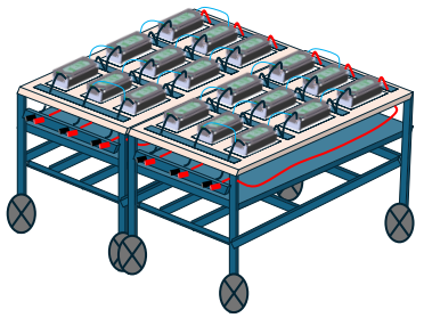

Figure 3 (right): DRAFT of the disposition of the modules by the robot and connections for characterization test.

Finally, the characterization station for battery modules, once the pack is opened, is being designed to integrate seamlessly into the overall layout of the disassembly and characterization cells. The primary goal is to minimize manual intervention while ensuring safe and efficient connections and testing procedures.

Ford Otosan

Our partners in Turkey have played a pivotal role in assessing the Turkish EV battery recycling landscape through a comprehensive LCA study focused on scrap from battery manufacturing. They initiated the collection of life cycle inventory data related to the recycling of this material, which is essential for evaluating the environmental impacts associated with battery recycling in Turkey. Sample material for the study was provided by the WEEE recycling company, EXITCOM.

Thanks to the continuous progress made by partners like BeePlanet and Ford Otosan, BATRAW is getting closer to achieving outstanding results every day.

Stay tuned to our social media channels to keep up with all our achievements!