Join us as we explore the significant contributions made by this dynamic duo!

The BATRAW project continues to advance, yielding impressive outcomes. Every partner is diligently striving to fulfil the project’s established goals and anticipated outcomes.

In this update, following our regular practice, we will outline the influence generated by two of our collaborators.

The first one is POSCO Holdings, a listed company based in South Korea that specializes in the production and supply of secondary battery materials. Starting in 2010 with the development of lithium extraction technology, expanding the business from its main focus on supplying steel products to producing the secondary battery materials has been continuing growth so far.

It supplies critical minerals such as lithium, nickel as well as cathode and anode active materials required for the secondary battery manufacturing industry. In particular, it leads in building and achieving a resource circular ecosystem by producing black mass at the recycling plant in Poland and transforming it to valuable metal sulphates by refining process in S. Korea. In line with these recycling plants, the recovered materials return back to the supply chain for the secondary battery industry again.

In the BATRAW project, it is responsible for utilizing recycled materials and producing NMC9 1/21/2 cell within the WP6. Prior to be supplied of recycled materials from the partners in the BATRAW project, it has been conducting coin cell tests using commercial recycled metal sulphates comparing with it by first production materials and optimizing the precipitation process in advance. The co-precipitated matters using recycled materials showed a little smaller size than it generated by first producing materials but there was no difference for the charge and discharge performance at all. With experience in cathode production and performance evaluation with cell manufacturing companies, evaluating the recycled materials produced through BATRAW and test cell production will be followed in coming months.

Second of all, we are going to get an insight into the activities done by the other partner. The following actor is a well-known French multinational automobile manufacturer which produces a range of different vehicles, aircrafts, and aircraft engines.

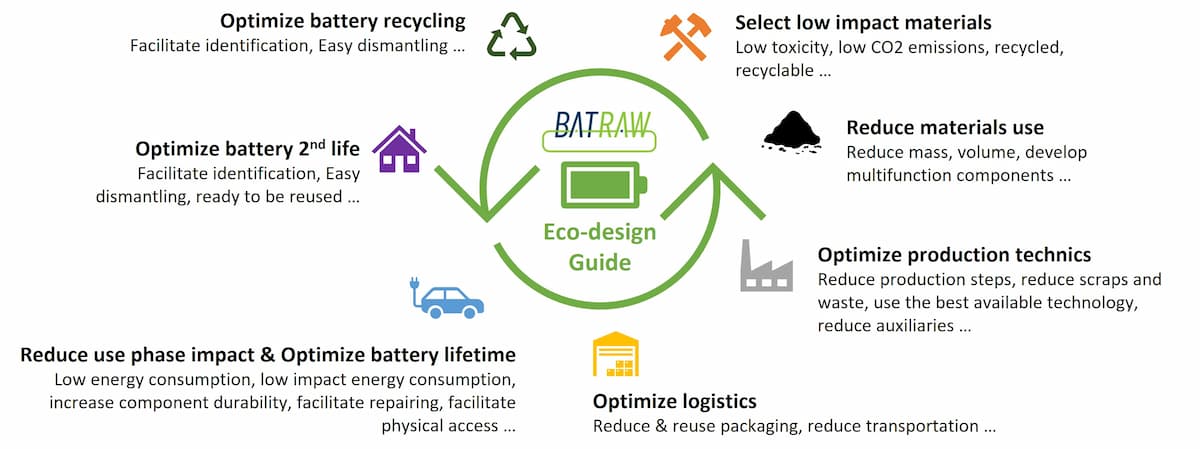

Renault, in collaboration with Ford Otosan, Minespider and Cesvimap, is working on an “Eco-design Guide for EV battery pack” in the frame of the BATRAW project. This guide will include eco-design recommendations at all life cycle stages of the battery: from manufacturing to repairing, reuse and recycling.

These guidelines will be based on:

- An environmental impact evaluation of an EV battery pack. The main environmental contributors will be identified, and impactful improvement perimeters will be proposed.

- Internal project expertise. The most common roadblocks to identification, storage, deactivation, disassembly, repair, reuse, recycling will be gathered and analysed. Macro rules will be proposed at conception level.

These eco-design rules will be transferred into the Battery Passport ID developed by BATRAW, in a questionnaire form. Doing so, specific information on battery design will be transferred to the adequate actor of the battery supply chain, to facilitate reuse, repair, and recycling.

This Eco-design guide will be delivered at the end of BATRAW project (Mid 2026), but do not hesitate to contact us for any question!