This month’s contributions are divided, but more united than ever!!

Let’s see what BeePlanet has been doing these months!

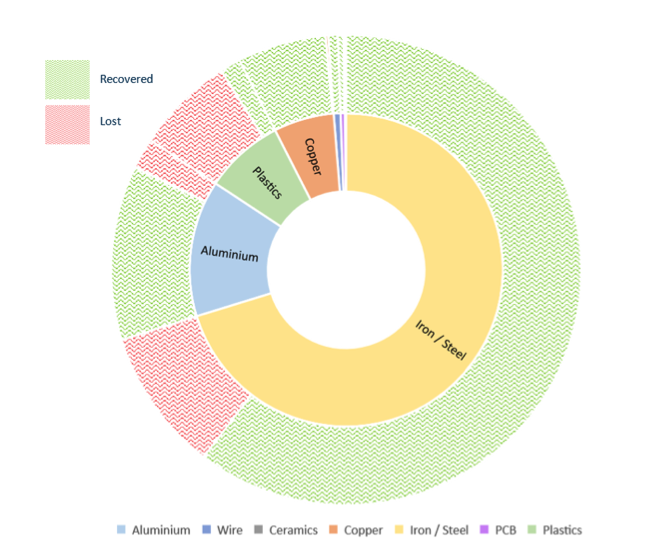

Within the WP3, BeePlanet is evaluating ways of valorising fractions from the dismantling process of battery packs. They have to evaluate the final quality of the materials and their suitability to be part of second life products. All the activities are carried out within a Circular Economy framework. They summarised their work in the following figure:

Recyclability of the materials originated from the disassembly of a Stellantis EV battery pack (excluding the modules and the BMs).

Regarding the dismantling process, they are designing and defining the working stations that will allow the identification, characterization, and deactivation of battery packs. These stations will be semiautomatic and integrated in the future disassembly pilot line for battery packs that will be implemented in a future phase at BeePlanet facility.

By the other hand, they are developing a comprehensive guideline of the steps to be carried out on the design and manufacturing of a second life BESS, as well as an end of line quality and safety protocols.

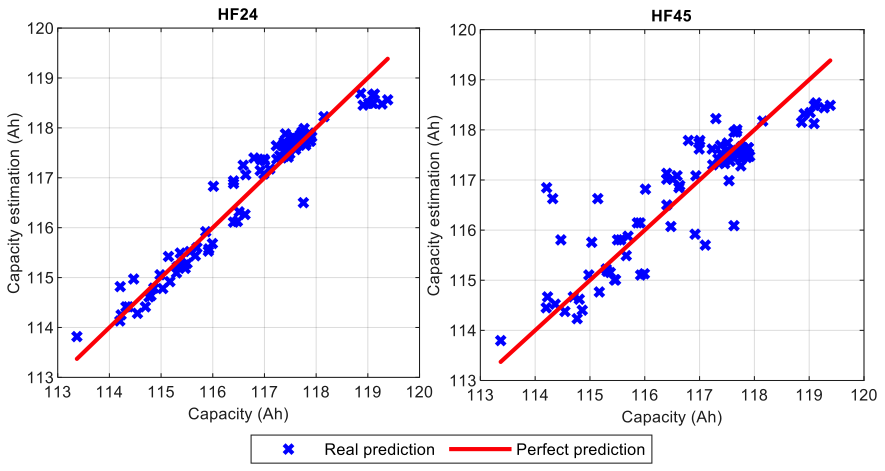

A tool to assess the internal state of EV batteries in a fast way was developed. This tool is framed in the second life methodology described in D2.5, which was also developed by BeePlanet Factory.

The challenge addressed in this tool is the knowledge of capacity in a battery, which helps to evaluate its feasibility for reuse. The characterization techniques generally used to measure capacity require excessive testing times. On the contrary, the tool proposed in this work is based on capacity estimation, through the extraction of features from battery operation and their use to model capacity evolution. This tool was tested on 97 second life Stellantis battery modules, reaching a RMSE of capacity estimation of 0.604% in 15 minutes. Thus, this characterization technique provides the required flexibility and adaptability to ensure its potential implementation either at cell, module, or battery pack level.

Real capacity vs. Prediction with the health features proposed for detailed and fast testing sequence.

A BESS was designed and fabricated using second life EV batteries, in this case, Stellantis batteries. Different tests and analysis were carried out before the fabrication of the prototype to validate the feasibility of the design and fulfilment of the requirements. The fabricated prototype consisted of a battery cabinet and a control cabinet with a capacity of 80 kWh.

Energy storage system with the battery and control cabinet.