During the last period of the BATRAW project, TORRECID mainly has researched in the frame of WP6, the improvement of synthetized LNMOs active materials for cathodes starting from commercial and recycled precursors. They have worked optimizing particle size control and other parameters involved in High Temperature Solid State Synthesis Process.

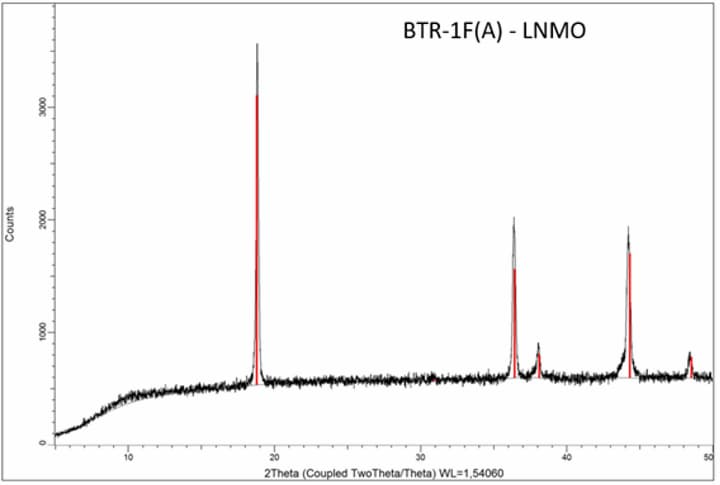

TORRECID has worked studying co-precipitation synthesis, with new commercial precursors, as well. The next plot shows the XR diffractogram of the best LNMO material obtained by solid state synthesis starting from commercials, so far.

In addition, TORRECID, as WP6 leader, has coordinated with the other partners different tasks involved in this Work Package and has organized periodic follow up meetings.

Finally, TORRECID has collaborated with the rest of WPs according to the required tasks, especially with the WP5 dedicated to obtention and supply of recycled precursors for the WP6 partners involved in synthesis of anode and cathode active materials.

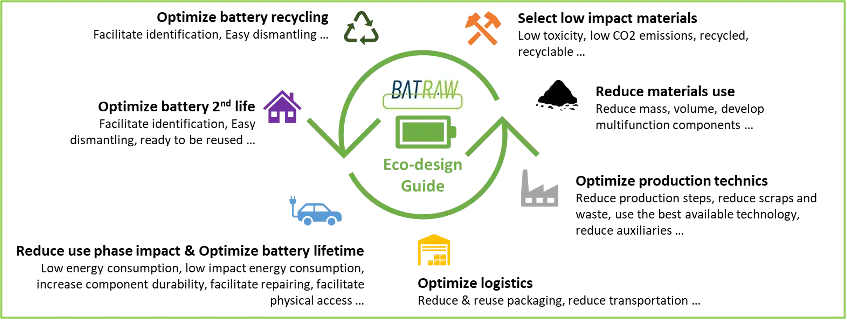

The next partner is Renault, which in partnership with Ford Otosan, Minespider, and Cesvimap, is actively engaged and responsible within the BATRAW project to develop an «Eco-design Guide» for EV Battery Packs. This comprehensive guide will provide recommendations covering all stage of the battery life cycle from manufacturing to repair, reuse, and recycling.

- Establishment of basic eco-conception rules: Simple and macro rules are formulated based on internal expertise and partner feedback. These rules aim to facilitate the dismantling process by considering various parameters such as pack, module, cells, BMS, and process steps like delivery, identification, and storage.

- Creation of relevant questions for the battery passport ID framework pioneered by BATRAW: Questions are prepared for battery producers to answer, facilitating information transfer to stakeholders such as dismantlers, second-life users, and recyclers. This integration involves structuring eco-design criteria enabling the efficient dissemination of critical battery design specifications across the supply chain.

- Provision of support documents for battery makers to implement eco-design: This includes offering materials lists, carbon footprints, and other impact assessments to assist in eco-design efforts.

- Conducting a life cycle assessment (LCA) study with LEITAT & Fraunhofer IKWS: This step involves comparing two battery pack designs with specific compositions and dismantling processes to evaluate environmental impacts.