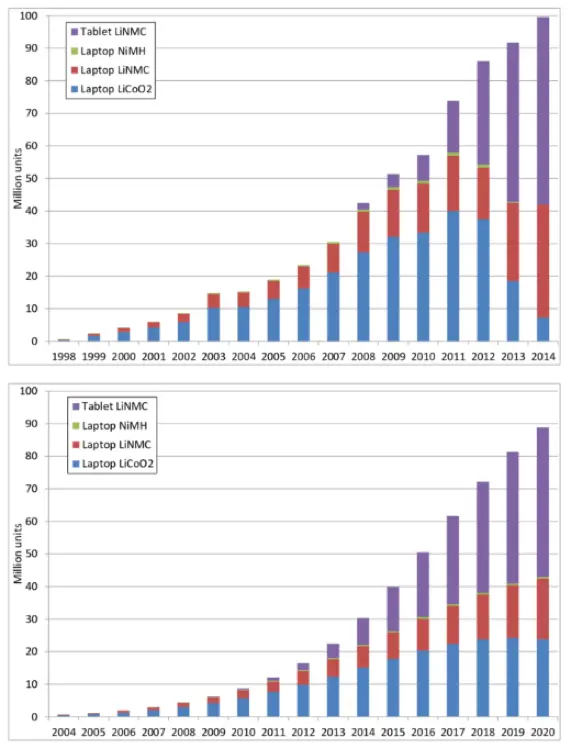

Indumetal Recycling, as WEEE manager, has observed an increase in the number of devices containing lithium batteries that arrive to their recycling facility in Bilbao. These batteries are found in all kinds of devices and may be of different shapes, sizes and chemistries. Unfortunately, the batteries often reach the recycling facilities in poor conditions, posing a significant risk due to their high energy capacity and reactivity. The first thing to do to avoid any type of risk that batteries may cause is to condition them, which involves deep discharge or battery deactivation. This process ensures safer storage, transportation, and handling of the batteries and is vital for the subsequent recycling steps in safe conditions.

Since the inception of the BATRAW project, Indumetal Recycling has made significant strides in the deep discharge of secondary lithium batteries sourced from all types of WEEE. For the BATRAW project, all kinds of batteries have been considered, including those from small electronic devices like wireless vacuum cleaners, mobile phones, and tablets, as well as batteries from individual e-mobility vehicles such as e-bikes and electric scooters.

Indumetal Recycling recently sent a batch of discharged batteries to Fraunhofer IWKS laboratories for further study in subsequent treatment stages. The results from these trials will guide the development of the mechanical pre-treatment process that will be implemented in the project.