Unlocking Potential: Disassembling EV Batteries and Assessing Exploitability

Let’s start with Indumetal and their latest developments!

Electric vehicles are becoming more and more popular since they help reduce greenhouse gas emissions. But have you ever wondered what happens to the battery packs inside these cars once they can’t power the vehicle anymore? BATRAW project partners are working to find new ways to make Electric Vehicles (EVs) even more environmentally friendly.

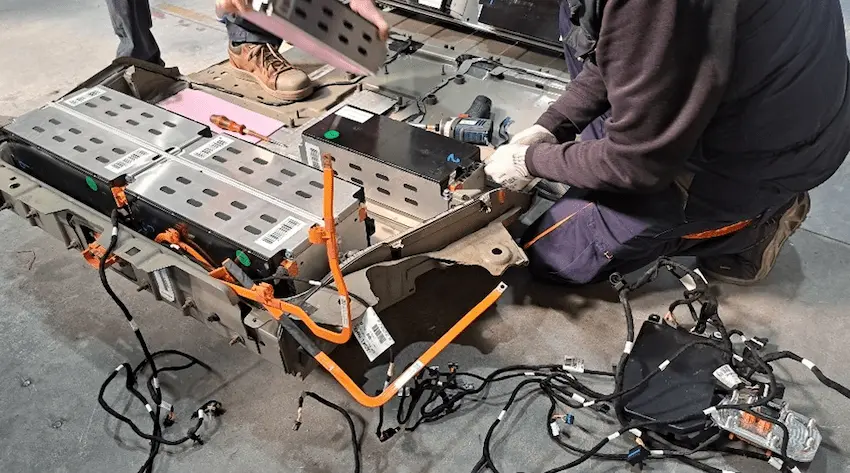

As part of the BATRAW project, Indumetal and BeePlanet carried out the disassembly of a Stellantis Battery Pack.

When an EV battery is no longer suitable for driving, the battery modules can be reused for energy storage systems. Therefore, the modules were extracted during the disassembly and sent to BeePlanet to give them a second life. Modules make up most of the battery’s weight, so they are quite valuable for reuse.

After taking out reusable modules, the remaining components were sent to Indumetal for further investigation regarding the recyclability potential of the materials.

Indumetal studied how much of each type of material could be recycled. Some materials, like copper, aluminium, and printed circuit boards, have high recyclability potential.

Other materials found to be part of the Battery Pack like ceramics and certain plastics, are harder to recycle and might be lost during the recycling process.

After doing all the calculations, it was determined that a big percentage of the materials in the battery could be efficiently recovered and recycled. This means they can be turned into secondary raw materials and, as a result, reduce the need for mining and dependency on foreign countries.

It’s not all easy, though. About a fifth part of the materials cannot be efficiently recycled and might end up being lost. This shows that recycling EV batteries can be quite tricky, especially when it comes to some plastic and ceramic parts. BATRAW has still a long journey to face the complexities and challenges involved in optimizing the recyclability of EV battery packs.

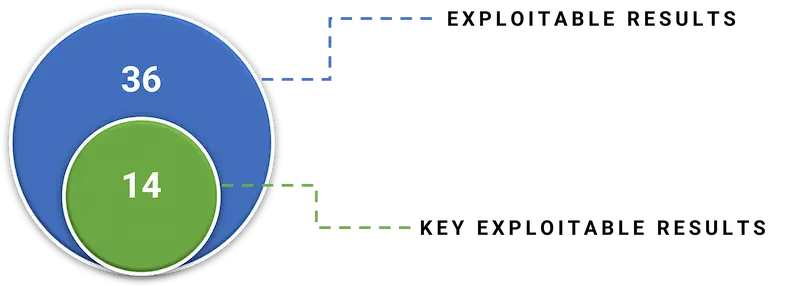

Continuing with ISLE and their main achievements since the last update, April 2023, ISLE has been working to deliver the preliminary Exploitation Roadmap and Business Strategy Plan (D8.3). This is an intermediate deliverable, and it outlines the results from ISLE’s work carrying out the Exploitable Results Assessment and a state-of-the-art analysis for the BATRAW project.

The Exploitable Results Assessment is a process implemented to identify BATRAW solutions with the greatest potential impact – known as Key Exploitable Results (KER). 36 Exploitable Results were identified and characterised with partner input through this process, and using a prioritisation criterion this has been narrowed down to 14 KER. Each KER has been analysed to identify any linked intellectual property, and their expected exploitation strategy – commercial or non-commercial.

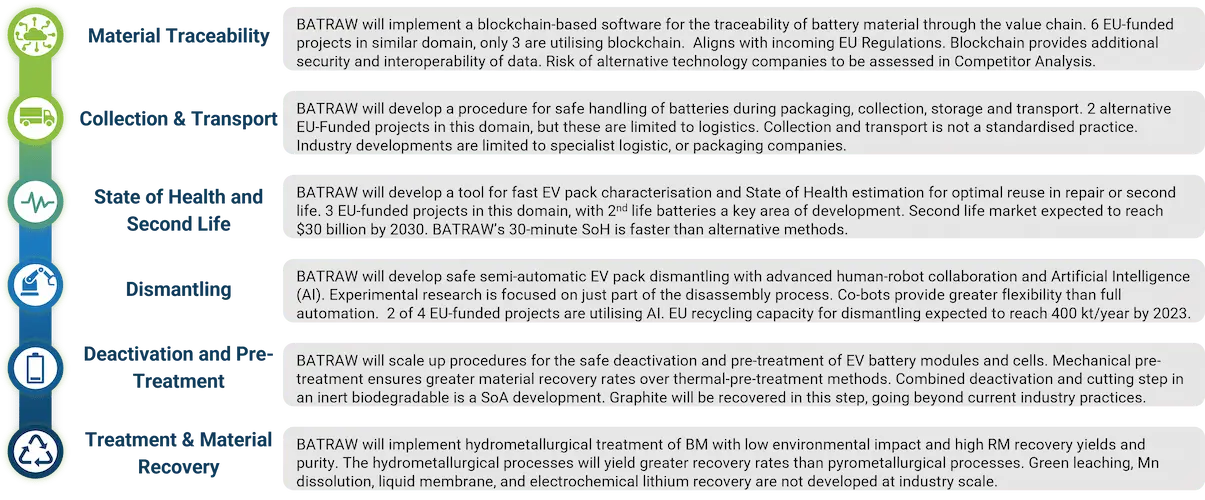

The state-of-the-art assessment gives an overview of the current landscape in the context of BATRAW solutions, including recent advancements, trends, methodologies, and leading practices. The state-of-the-art assessment follows BATRAW’s added value across the recycling chain, analysing research and industry in each domain to identify the highest level of development, highlighting the position of BATRAW’s solutions.

The next stages in ISLE’s work involves developing the business strategies for the commercially exploitable KER, informed by, and aligned with a detailed Market and Competitor Analysis to provide an understanding of drivers, barriers, dynamics, and benchmark against competition. ISLE will also start planning the organisation of the Innovation Workshops (market focus workshops), with the aim of accelerating the market uptake of the BATRAW innovative solutions among potential end-users and key industry actors.