Policy Recommendations: Better Regulation In The European Union

CEPS leads the policy work of BATRAW and develops policy recommendations based on the project’s results to feed ongoing regulatory developments. In recent months, CEPS conducted dedicated research on the Digital Product Passport (DPP), which has received a lot of visibility in EU policy circles in the context of the Ecodesign for Sustainable Products Regulation (ESPR) and the EU Batteries Regulation.

Engaging (policy) audiences

To engage a wider audience and contribute to the policy debate on batteries circularity, CEPS organised a BATRAW policy event in Brussels. A side session of the Raw Materials Week in November 2023, the event was dedicated to the battery passport. Speakers from battery supply chain actors, NGOs and research discussed the potential of the battery passport to enable more transparent and sustainable supply chains. Key insights from the event included:

- Digital product passports, including the battery passport, are useful tools for conveying information, but a persisting reluctance to share information hinders effective tracing of battery components and related environmental impacts.

- Common standards aimed at interoperability are essential for data exchange. Trust in data verification is paramount, facilitating ease of access without overwhelming consumers. A standardised approach can facilitate more informed consumer choices.

- The battery passport, rooted in an industry with established information exchange and high recycling rates, can serve as a model for DPPs in other sectors.

You can find the event recording at the CEPS website: https://www.ceps.eu/ceps-events/the-battery-passport-as-an-enabler-for-sustainability-and-transparency-across-supply-chains/

Providing policy recommendations

Partly informed by the outcomes of this event, CEPS recently published a policy paper, ‘Implementing the EU digital battery passport: Opportunities and challenges for battery circularity’. The report delves into the new EU regulatory framework for batteries and the expanding EU DPP landscape. It identifies crucial opportunities and challenges for implementing battery passports based on qualitative data collected from companies at different segments of the battery value chain.

The findings indicate that the key strength of the battery passport is its potential to break down information silos among supply chain actors, supporting recycling and reuse processes. It also helps to increase transparency about carbon footprint impacts across battery supply chains. At the same time, implementation challenges need to be addressed: For example, concerns about data confidentiality and a lack of standards to ensure interoperability, and missing clarity in certain aspects of the existing legislation.

Therefore, the paper recommends that more clarity be provided about battery passport-related responsibilities, that passport data interoperability be supported, and that a platform be created for sharing best practices of battery passport initiatives.

You can read the full paper here: https://www.ceps.eu/ceps-publications/implementing-the-eu-digital-battery-passport/

Advancements in Battery Recycling Pretreatment: Paving the Way for a Sustainable Future

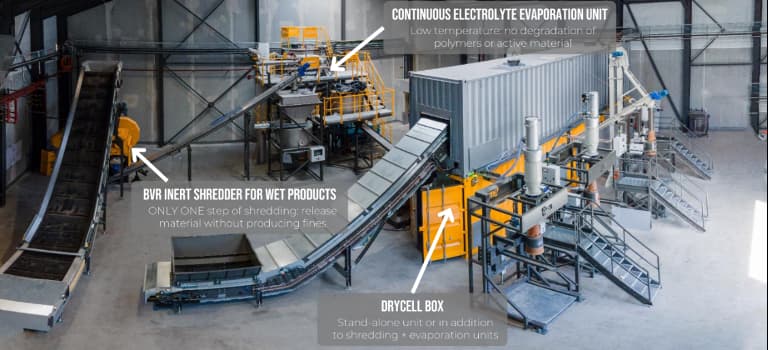

As planned, MTB has launched its battery pretreatment pilot line, the Zero Waste Battery (ZWB) line, processing from end-of-life battery packs to black mass.

The installation of a battery pretreatment pilot line marks a significant milestone for MTB in connection with the battery recycling expectations. This facility processes end-of-life battery packs, extracting valuable materials such as copper, aluminum, plastics and black mass.

The ZWB pilot project is a game-changer. It operates in two distinct phases:

- Drycell BOX (September 2023): Designed to process electrolyte-free scrap, the Drycell BOX demonstrates efficient separation techniques. It prepares the groundwork for subsequent wet processing.

- Wet Unit (Since January 2024): This unit handles scrap and batteries with electrolyte. By fine-tuning the sorting process, they achieve higher recovery rates and enhance material purity.

MTB is carrying on with the phase of adjusting and fine-tuning to define the right operating parameters before launching large-scale trials in the second quarter of 2024 to validate performance at a nominal flow rate of 1t/h.

As part of the BATRAW project, they have also worked with other partners. Tests conducted with ORANO as part of the BATRAW project were crucial. Scrap without electrolyte was used to validate the sorting sequence, confirming recovery rates and assessing material purities for the secondary sorting pilot for ORANO.

In collaboration with Minespider, they focus on traceability. Their goal is to anticipate the battery passport for recycled material flows. By ensuring transparency and accountability, they build trust in the circular economy.

MTB experts are committed to understanding the environmental impact. Their ongoing Life Cycle Analysis includes recycling modeling. Calculating avoided carbon emissions provides a tangible measure of the benefits of end-of-life battery recycling.

Last but not least, in April, MTB will host the next general meeting of the BATRAW project. Partners will gather to explore our pre-industrial pilot plant and delve deeper into our recycling capabilities.

By refining the design of mechanical shredding and sorting processes, they optimize resource recovery and minimize waste.

Stay tuned for more updates as we continue our journey toward a greener, more sustainable future!