Incredible progress made by these big three 💪

This is the end of an era, we have completed our calendar of contributions and, since the start of the project, each partner has submitted their progress updates every month.

But do not be sad, an end is only a beginning, we will continue working to bring you fresh contributions every month, as always!

The first partner to contribute this September is LEITAT. It is a Spanish leading Research and Technology Organization (RTO) with a solid track record on existing and future energy storage solutions for stationary, transport and wearable applications. The group has strong knowledge on electrochemistry, and advanced battery materials and components. Available infrastructures allow the synthesis of materials, their processing from ink to dry method, their assembly and characterization. Test benches are also available for the electrical, mechanical, and thermal assessment of devices up to the battery module level.

As coordinator of the BATRAW project, LEITAT has the responsibility to guarantee the quality and efficiency of the project implantation, by managing and supervising the activities of the consortium, composed by 15 partners from 7 different countries, covering the full value chain for battery recycling. It is also responsible for liaising with the funding authority, the European Commission.

Moreover, it covers crucial technical development in the project through the whole value chain. LEITAT is involved on the battery disassembly, metal recovery (e.g. electrochemical Li recovery and Co & Ni recovery using membranes) and environmental and social assessment activities.

Actively engaged in business opportunities, not only in Europe, but also in Turkey and South-Korea, the project coordinator has received POSCO Holdings, to explore collaboration in the materials sectors.

Our second partner is MTB Group, which is the only player in the world with the dual competence of recycler and manufacturer of recycling equipment. “We know customers’ issues, we master technologies, we offer best solutions.”

For 42 years, more than 50,000 tons of waste are processing each year at the company’s historic recycling site in France. A commitment to Zero Waste and an ambitious premium positioning to provide raw materials (RMs) with very low environmental impact drive our innovation.

MTB Manufacturing designs processes and manufactures equipment for recycling industrial waste (cables, WEEE, shredding residues, tires, etc.). An innovative player that invests in its production facilities and in R&D (8% of annual turnover) for the future of our children and participates in numerous ecodesign projects to develop customized solutions for technical and technological waste.

By participating in several European consortia, the MTB teams have continued their R&D work aimed at developing a robust, safe and efficient recycling solution for LIBs. In concrete terms:

- Shredding of EV modules

- Mechanical separation and sorting of black mass

- Purity analysis and supply of black mass to partners for further testing.

The challenge for MTB is to continue and optimize its developments in the field of Li-ion battery recycling, particularly in the area of shredding, for which we have developed a new shredder. MTB design team also develop unique solutions for secondary sorting of materials to maximize black mass recovery rates and purity.

The main objective is to maximize the LIB recycling rate, which contains critical raw materials, and to reduce electrode metal contamination (aluminum and copper) in black mass. This approach should make it easier for BATRAW partners to extract metals through hydrometallurgy.

The overall recycling rate exceeds 85%, and 95% of the black mass (that contains strategic metals) is recovered with a purity of over 98%.

This work will continue until the end of the BATRAW project and will be reinforced with the commissioning of the Zero Waste Battery recycling pilot at MTB.

The last one is our Castellón based TORRECID, S.A., which participates as partner in BATRAW in the validation of recycled materials. Contribution of TORRECID S.A. towards the objectives of BATRAW are aligned with the recovery of battery grade RMs for active material synthesis.

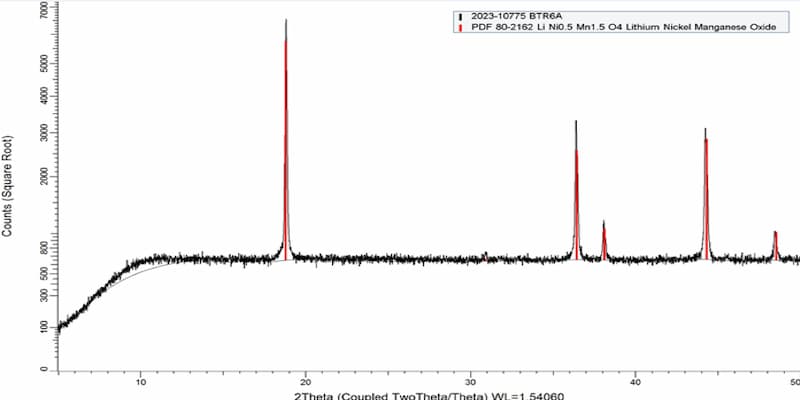

During the first part of project and within Work Package 6 activities, TORRECID has supported activities of partners and researched in the use of recycled precursors for the synthesis of LNMO (LiNi 0.5Mn1.5O4).

TORRECID has demonstrated initial recovery of some precursors for the LNMO, defining cost effective and with low environmental impact process for solid state synthesis of cathode material. Assessment of materials are being done in close relation with LEITAT, CEA and POSCO. Activities of TORRECID covers material synthesis and characterization. In the next figure, as example, XRD of a synthetized in TORRECID LNMO material is shown: